FDM 3D Printing

What is 3D FDM Printing?

Have you ever been working and one small part of your equipment breaks? You go online to find a replacement only to find out that particular part is almost as expensive as replacing the entire item, or worse; it’s no longer made!

We currently have five active FDM (filament) 3D printers available...

each with their own capabilities depending on the project you are working on.

Bambu

"CLIPPY"

Bambu P1P - Upgraded to P1S with Dedicated Single-Spool Dryer

Description: P1S acquired by HackPGH July 2023, upgraded to P1P June 2024

Complete Hotends:

- 0.2 (stainless steel)

- 0.4 (hardened steel, ObXidian, and Diamondback)

- 0.6 (hardened steel)

- 0.8 (hardened steel)

Features:

- Build Volume: 256x256x256mm/10x10x10”

- Enclosure enables high-temperature filament printing

- Dedicated dryer allows more seamless printing of “difficult” filaments such as Nylon, PVA, and TPU

- Print speeds up to 500mm/sec

- Built-in camera for remote viewing

"WALL-E"

Bambu P1S Combo with Four-Spool AMS

History: Acquired by HackPGH January 2024

Complete Hotends:

- 0.2 (stainless steel)

- 0.4 (hardened steel, ObXidian, and Diamondback)

- 0.6 (hardened steel and ObXidian)

- 0.8 (hardened steel)

Features

- Build Volume: 256x256x256mm/10x10x10”

- Current AMS system allows for multi-material printing

- Enclosure enables high-temperature filament printing

- Built-in camera for remote viewing

- Print speeds up to 500mm/sec

- Built-in camera for remote viewing

Two Bambu X1-Carbon Combo printers -

"MARVIN" and "H.E.L.P.eR."

each with Four-Spool AMS

History: Acquired by HackPGH January 2024

Complete Hotends:

- 0.2 (stainless steel)

- 0.4 (hardened steel, ObXidian, and Diamondback)

- 0.6 (hardened steel and ObXidian)

- 0.8 (hardened steel)

Features:

- Build Volume: 256x256x256mm/10x10x10”

- Four-color & multi-material capability

- Enclosure enables high- temperature filament printing

- Built-in camera for remote viewing

- High quality printing with 7 μm Lidar Resolution

- Print speeds up to 500 mm/sec

- Dual Auto Bed Leveling

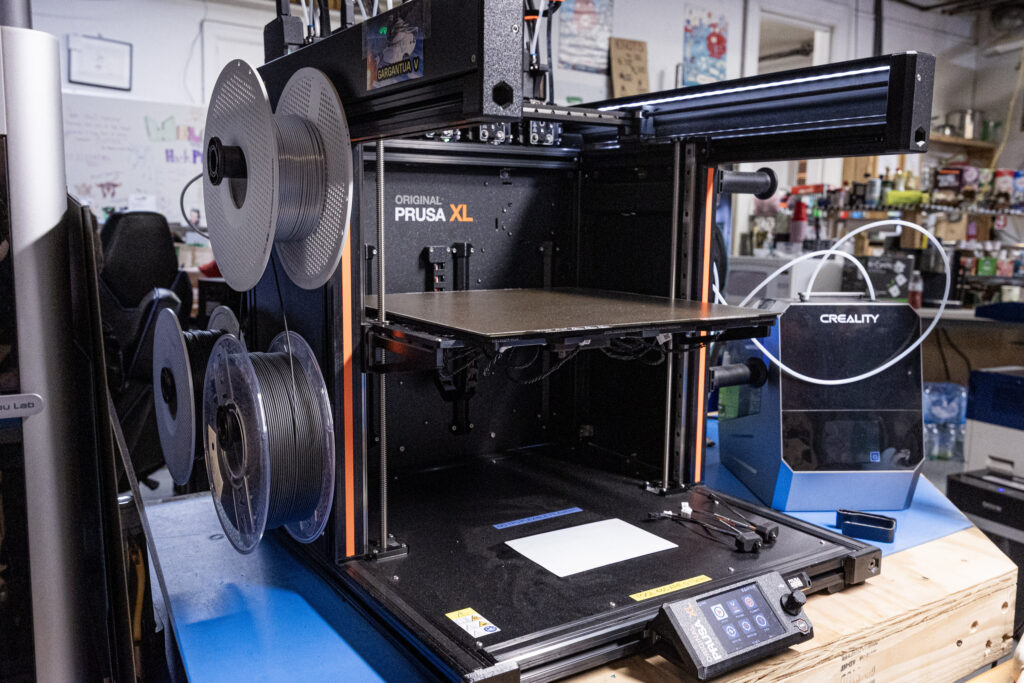

Prusa

Prusa XL with Five Toolheads

"GARGANTUA V"

History: On permanent loan to HackPGH from Becky Zajdel as of August 2024

Nozzles:

- 0.4 (ObXidian High Flow)

- 0.6 (ObXidian)

- Several adaptors that allow printing as detailed as 0.15mm

Features:

- Build Volume: 36x36x36mm/14.17×14.17×14.17’’

- Five independent extruders capable of zero-waste changes between colors or even materials

- Segmented heatbed for heating efficiency

- Print speeds up to 200 mm/sec

- Wireless printing via Prusa Connect/Prusa link

3D PRINT AREA RULES & GUIDELINES

RULES FOR OUR FDM/FILAMENT 3D PRINT FARM:

All five FDM/Filament 3D printers are bookable on HackPGH’s Skedda page. As our 3D printers are becoming more popular, we ask that you follow the following rules and guidelines:

BOOKING & USER GUIDELINES

Click to expand...- A training session is required before using the Bambu printers if you have never used an FDM 3D printer before.

- The Prusa XL is on loan. Per HackPGH’s general Rules & Regulations, you must be “checked off” or given permission by Becky Zajdel or a 3D Printer Shop Lead before using the Prusa XL.

- “Helper” the Bambu X1C is also on loan, but as long as you have been trained or printed with any other Bambu printer independently, then you can use it.

- Always write the following information about your print on the whiteboard in front of the printer:

- Your full name

- What is printing

- “EFT” Estimated Finish Time

- You must “book” a printer on Skedda if you are printing (or planning to print) something that will take more than three hours.

- Do not use or book more than two 3D printers at once unless you have prior approval from a 3D Print Shop Lead or Board Member.

- Try to limit extra-long prints (6+ hours) to overnight or early morning hours: Midnight to Noon (rules during these hours are relaxed in Skedda)

- You cannot book more than one extra-long print (6+ hours) during the “busy hours” of Noon to Midnight unless you have approval from a 3D Print Shop Lead or Board Member.

- You can book up to two XL prints between Midnight and Noon if you leave at least one printer free to someone’s use, but both prints must be complete by Noon.

- If you cannot be in the shop for the duration of your print, post in Slack on #3d-printing and/or write your name and contact info on the printer’s whiteboard:

- Which printer you using and how long is left on your print

- Instructions on where to put the completed print or what to do in case there is a failure.

- Your prints are your responsibility! If you do not post or notify others in some way, your print may be moved or canceled if there are any issues.

- HackPGH clubs, classes, and projects take precedence over personal prints.

GENERAL USE & MAINTENANCE GUIDELINES

Click to expand...- Getting an error message you can’t fix? Is something “off”? Turn off the machine, put an orange “borked or broken” tag on it, and post the problem in the #3d-printing Slack channel!

- Prusa offers 24/7 online chat assistance.

- Make sure you follow and apply the settings on the filament roll when preparing and slicing a print, especially when using different brands of filament from the default settings.

- All five printers are equipped with hardened+ 0.4 nozzles/hotends as a default. Do not switch out nozzles/hotends unless you have been trained!

- If you need to switch out a nozzle (0.2 for greater detail, 0.6-0.8 for speedier prints):

- Create a label with HackPGH’s label maker (or a piece of painters’ tape) stating the nozzle size and type and affix it to the front of the printer. Unless the old nozzle/hotend is damaged, do not throw it away! Place it into the appropriate storage container until you are finished with your print(s). For example, if you want to use a 0.6 hardened nozzle on the X1C, remove the hotend and place it in the clear hotend container inside of the larger “Bambu accessories” bin, and affix a label to the front of the X1C saying: “0.6 hardened nozzle.”

- When you are finished with your print, replace the original 0.4 hotend/nozzle and replace or create a new label.

- Do not replace the nozzles on the Prusa unless you are trained to do so. You MUST re-calibrate the Prusa XL after any nozzle changes on any of the five extruders!

- Only regular and matte PLA and PETG can be used with 0.2 nozzles. NEVER put carbon fiber or cosmetic filaments such as glitter, galaxy, glow in the dark, or silk through a 0.2 nozzle.

- Most prints do not need glue on the plate! Try adjusting bed/nozzle temperature or activating brims and rafts first. If you are still having bed adhesion issues or running low on filament, then use a small amount of the appropriate type of glue. Do NOT overuse.

- Always clean off the build plate after you are finished printing!

- Remove all filament and prints

- Only use the designated scrapers to remove stuck prints.

- If there is glue residue, take the plate to the sink and use HOT water with soap if necessary to clean it off. Dry the plate completely before returning it to the 3D printer or plate storage.

FILAMENT, PAYMENT, & STORAGE

Click to expand...-

- Click here to compare different types of filament, their general properties, advantages, disadvantages, and more.

- HackPGH provides a variety of PLA & PLA Matte filament free for its members to train, experiment, prototype, or print small parts or items. We want to continue to provide filament, so please follow these rules:

- Return spools to where you found them.

- Save all empty Bambu spools! Do NOT throw them away!

- PLA & PLA Matte is free until you reach 250g (a quarter of a standard spool). Scan the QR code on the PLA shelves to donate $5 for every 250g you use.

- HackPGH also provides several types of filaments at a cost of $8 per 250g used:

- PETG – HF and Transparent (located on shelf above computer)

- PLA cosmetic – glitter, galaxy, silk, dual-color, and glow (red bin)

- Carbon fiber filaments (bookshelf)

- Need a special filament for a part or special print? HackPGH has a number of TPU, Nylon, ABS/ASA, and metal/wood fiber-filled filaments in storage. Contact a 3D Print Shop Lead or the Board of Directors to gain access. You will need to pay before being given access.

- HackPGH’s filaments are available on the honor system: Do not abuse it. Security cameras are located in the print farm area to prevent theft. If you print a large amount of small prints for personal use, please contribute towards filament replacement. If a Shop Lead or Board Member notices wasteful use of filament, your access to the 3D printing consumables or even printers may be suspended.

- Do not leave the following filaments out:

- PETG

- Nylon (PA6)

- TPU

- ASA

- ABA

While most PLAs and regular PETG can be left out, the filaments above must be placed in one of the seven dryer spots or vacuum-sealed with desiccant packs after removing the spool from the printer, AMS, or printer-adjacent dryer.

- HackPGH has three filament dryers with a total capacity of seven spools:

- Creality Space Pi Plus (2-roll capacity)

- SUNLU Dryer Box S4 (Dehydrator with rapid heating) (4-roll capacity)

- Creality Dryer Box Pro 2.0 (1-roll capacity, next to Clippy)

- We also have vacuum storage kits with bags and desiccant packs. ALWAYS dry and vacuum-bag filament after using except for PLA & PLA Matte. Vacuum seal the cosmetic filaments – no need to dry – before placing them back in the large red bin.

- Click here for HackPGH’s chart of recommended filament drying times and temperatures. If a spool of “older” PLA is giving you problems with stringing or bed adhesion, you may want to dry it out before attempting to re-use it.

- If the filament in the chart shows that it is required to print with desiccant or from a dryer box, we recommend that you use Clippy and load your filament into the single-spool Creailty dryer next to it. You can then feed your filament through the silicone hole and into the printer’s PTFE tube manually.

- Post on Slack’s #3d-printing channel and/or inform a Shop Lead if you use the last of a spool.

- Members are welcome to bring their own filament and store them in the storage room or one of the two member filament bins under the PLA shelves. Clearly label your filament spools! HACKPGH is not responsible for stolen or missing items, including personal filament.

-